Completed the retest on the Overhead (4G) test plate for Dual Shield FCAW certification. I had previously passed the Vertical (3G) test and not passed the overhead due to excessive porosity.

Not a problem this time. We switched out from the wire made by the black and yellow European company to the red, white and black U.S. company’s wire. Normally, I would just blame myself for the error, but the contrast between the results from each was too much. Plus, I wasn’t the only one. Apparently, this batch of “all position wire” was not quite up to the task.

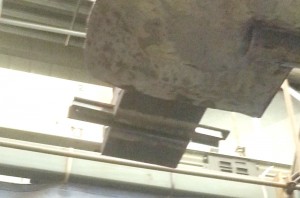

Here was my view of the test plate as I took a break to let it cool down a bit

That was six feet, ten inches off the ground per my tape measure. I found a booth that I could get the ventilation and table up high enough that I could stand under it with my boots and hood on. On my previous test, I had to sit below it while the slag rained down upon my lap. I was able to hang it off the right side of the table and keep my left shoulder blade resting on the pole in the back of the booth for balance.

12 passes later and the one inch thick plate’s V-groove was full. The test allows a 1/8in reinforcement height above the plate for cover passes, I was at 1/16th at my highest point.

Cut and bent and here is the result.

You can make out the fusion in the V-groove of the plate in this picture.

My apologies for being too dumb to operate my phone and desktop at the same time and deleting the shot of my 3G and 4G plates sitting next to each other like bros.

Not sure what I’m going to do next. I still need to finish vertical TIG aluminum and both flat and vertical stainless steel TIG.

A problem has arisen and I will likely be coming back for Winter Quarter. Not sure if it will be full time or at night yet. While a MIG cert this quarter is not out of the question, seeing as how I have less than 14 days left in the quarter, it will be tight.

I’m thinking that if I come back full time I may do the MIG cert and a Stick cert and try for a Sanitary Stainless Steel pipe cert, even though I’ll likely have to buy my own pipe to practice on since it isn’t in the curriculum.

My instructor likes that plan a lot. I only hope my student loan folks do too.

Do they bend the hell out of the aluminum test sections anywhere near as much as the steel? I’d be surprised if even an unwelded section of aluminum bar could take that much abuse without small cracks popping up.

One of the downsides to things like Aluminum and Stainless is that they aren’t really used for structural purposes. The testing for those certifications actually takes place away from the school, usually through an employer. But I can practice them at the school with their equipment so as to make a decent run at passing an employer’s test.

A boat builder, for instance, will want you to run a number of beads on scrap steel that they can maybe x-ray or radiograph test. But if you’ve not had much experience with aluminum, they’ll be able to see the quality of your welds just through visual examination.

What size SS pipe do you need? I’ll keep an eye out during my regular stops at the recycling yards.

Not sure at this time. I’ll ask the instructor. Thanks, Don.